86-752-2203959

Description

Pleated High Flow Cartridges are designed to be used in different filter housings which install 1 to 37 pieces cartridge filters. Pleated high flow cartridges are made by polypropylene media, large filter area and high filtration efficiency exceed 99%. High flow cartridge filters can be used for a variety of important industrial applications for different high flow rate request.

High flow pleated cartridges are used as a direct replacement to 3M 740 series elements, reduce the number of normal 2.5" OD filter cartridges save much cost and manpower, longer service life and high dirt holding capacity.

Feature

1. Easy to install and replace, save manpower and times

2. High flow pleated cartridges are high intensity and long service life

3. Wide range of chemical compatibility and suitable for a variety of fields

4. Pleated high flow cartridges are large flow rate and high dirt holding capacity

5. Direct replacement to 3M 740 series elements, longer service life and high dirt holding capacity

6. The sealing O-ring design no bypass to improve the filtering efficiency of high flow cartridge filters

Application

1. Power plant condensed water filtration

2. Chemical industry, microelectronics industry

3. R.O. pre-filtration and sea water desalination

4. Petroleum chemical industry related filtering

5. Pharmaceutical ingredients, solvents,and water filtration

6. Drinking water, edible oil, beverage,beer, milk filtration

Specification

| Filter Media | Polypropylene Pleated |

| Length | 20"(508mm), 40"(1016 mm), 60"(1524mm) |

| Outside Diameter | 6 inch(152mm) |

| Filtration Rating | 1μm, 3μm, 5μm, 10μm, 20μm, 40μm, 70μm, 100μm |

| Support/Drainage | Polypropylene (PP) |

| End Cap Material | Glass fiber reinforced Polypropylene (PP) |

| Center Core | Polypropylene |

| Outer Support Cage | Polypropylene |

| Seal Material | EPDM, Viton |

Feature

● Easy to install and replace, save manpower and times

● High flow pleated cartridges are high intensity and long service life

● Wide range of chemical compatibility and suitable for a variety of fields

● Pleated high flow cartridges are large flow rate and high dirt holding capacity

● Direct replacement to 3M 740 series elements, longer service life and high dirt holding capacity

● The sealing O-ring design no bypass to improve the filtering efficiency of high flow cartridge filters

Application

● Power plant condensed water filtration

● Chemical industry, microelectronics industry

● R.O. pre-filtration and sea water desalination

● Petroleum chemical industry related filtering

● Drinking water, edible oil, beverage, beer, milk filtration

● Pharmaceutical ingredients, solvents, and water filtration

Performance

Operation Date for MF Series Pleated High Flow Cartridges

| Maximum Operating Temperature | 80℃ |

| Maximum Differential Pressure | 3.4Bar @ 82℃ |

| Replacement recommend pressure drop | 2.4Bar @ 20℃ |

| Suggested Maximum Flow Rate | 40"(1016 mm) - 1300 LPM |

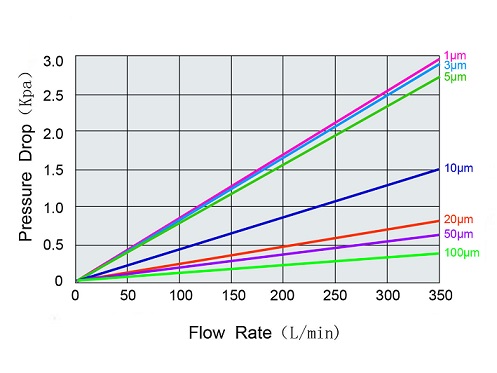

Flow Rate for 40" MF Series Pleated High Flow Cartridges

Tech Support

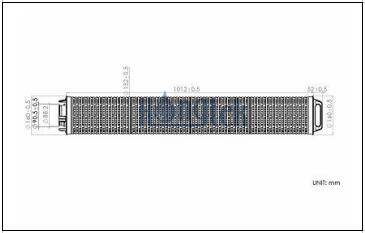

CAD Drawing for 40" MF Series Pleated High Flow Cartridges

| ● Inside core and outside cage ensure good performace under high pressure ● Long service life and easy to replace to3M 740 series high flow filter elements ● Pleated high flow cartridges are suitable to install for normal high flow filter housing ● Pleated cartridge save much cost and manpower, longer service life and high dirt holding capacity ● Good sealing O-ring design no bypass, high flow rate, low delta pressure & high filtration efficiency | ||||||||||

Oder Information

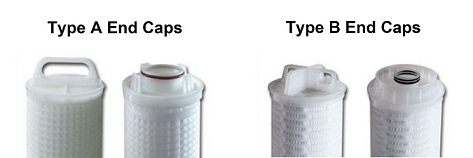

| MF | Material | Length | Filtration Rating | End Caps | O-ring Material |

MF Series Pleated High Flow Cartridges | P = PP Pleated | 20 = 20"(508mm) | 1 = 1μm | A = Type A End Caps | E = EPDM |

| 3 = 3μm | |||||

| 5 = 5μm | |||||

| 40 = 40"(1016mm) | 10 = 10μm | V = Viton | |||

| 20 = 20μm | B = Type B End Caps | ||||

| 40 = 40μm | |||||

| 60 = 60"(1524mm) | 70 = 70μm | ||||

| 100 = 100μm |

For Example:

MF-P-40-1-A-E

MF Series Pleated High Flow Cartridges - PP Pleated - 40" (1016mm) - 1μm - Type A End Caps - EPDM